Technologies for processing greeting cards and gift boxes

Our own machinery and many years of experience allow us to process, not only greeting cards using special graphic techniques...

We use this technique mainly for printing text and graphics to complete the overall impression according to the feelings of the artist. The range of foils is unimaginably wide, differing mainly according to the type of printed material or according to the type of colours: metallic, matt, glossy or monochromatic. A specific type of foil without a carrier is gold foil, which is used mainly in art bookbinding.

Where, in addition to the profile, the colour transferred from the embossing foil is also visible on the motif after printing. The ink is transferred from the foil to the printed material by the pressure and heat that the book forms develop. By the pressure of the printing surfaces, the foil is pressed into the paper and the ink is released at the places of pressure and temperature.

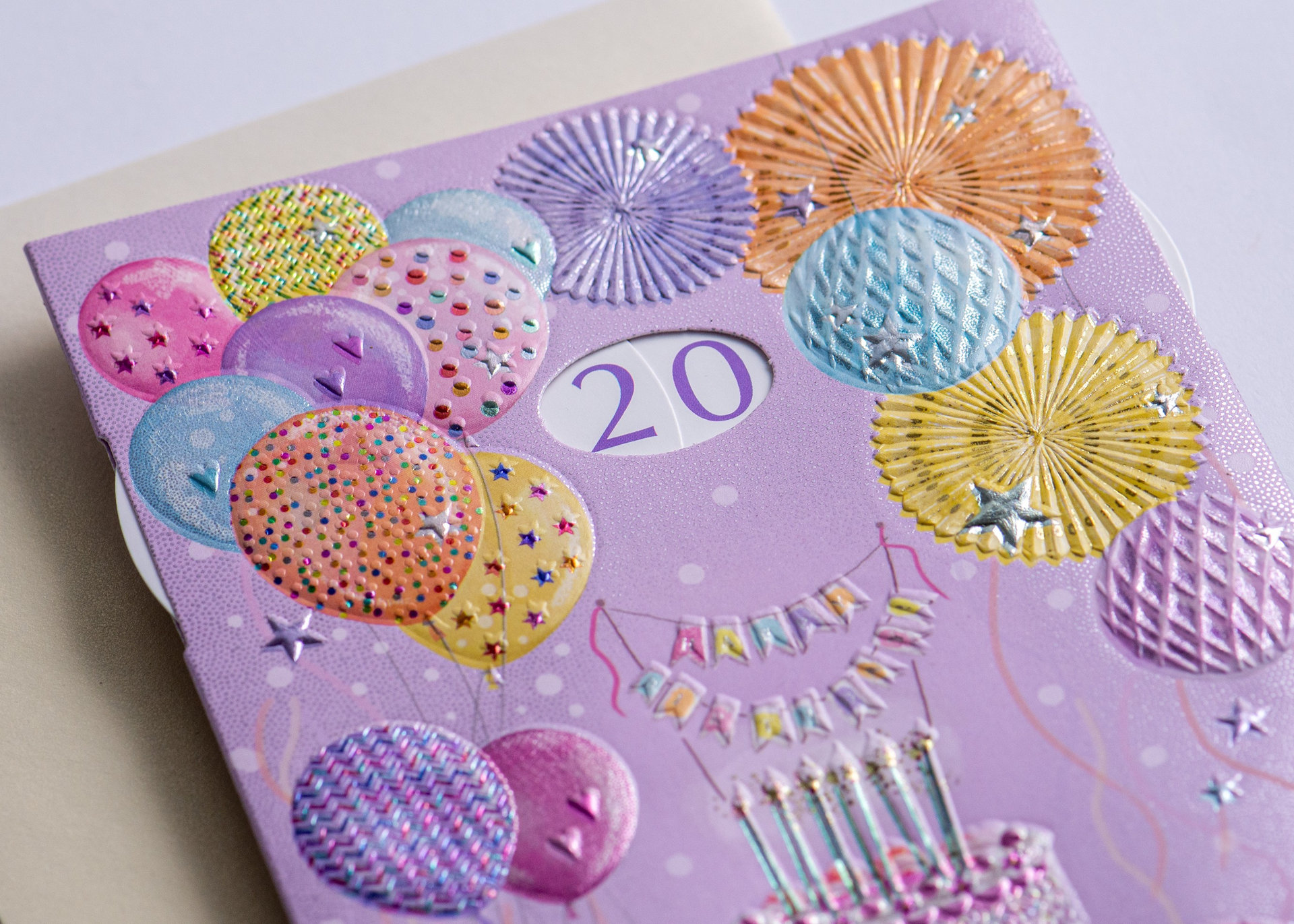

Thermographic printing gives the prints an interesting plastic look. It is about creating a relief by the action of heat. A thermographic powder is applied to the not yet dried adhesive print, which polymerizes under the action of heat. During polymerization, the powder increases its volume, and in this way an irreplaceable relief is created. The very appearance of the relief is determined by the powder used, which can be pearly, metallic, glittery or simply white.

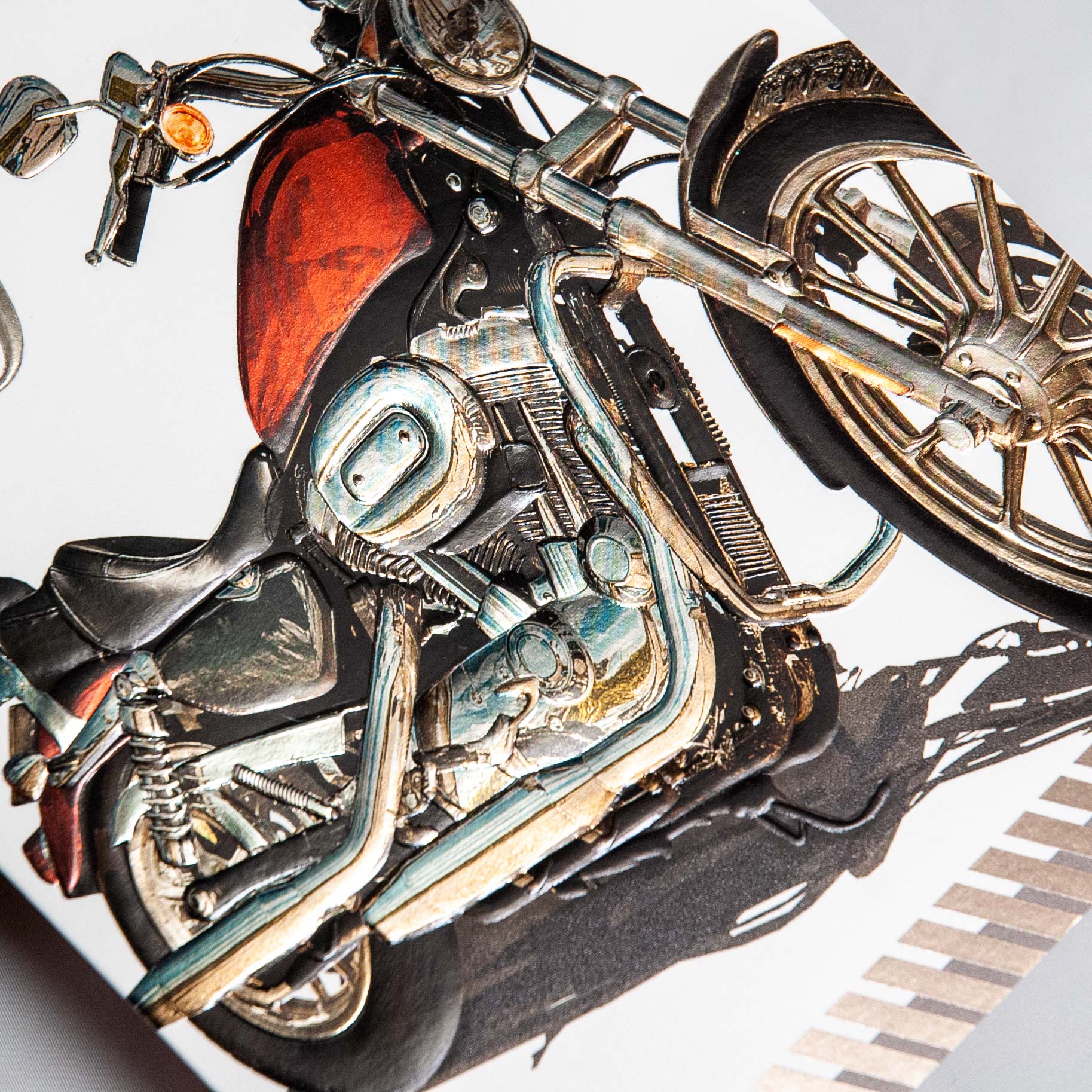

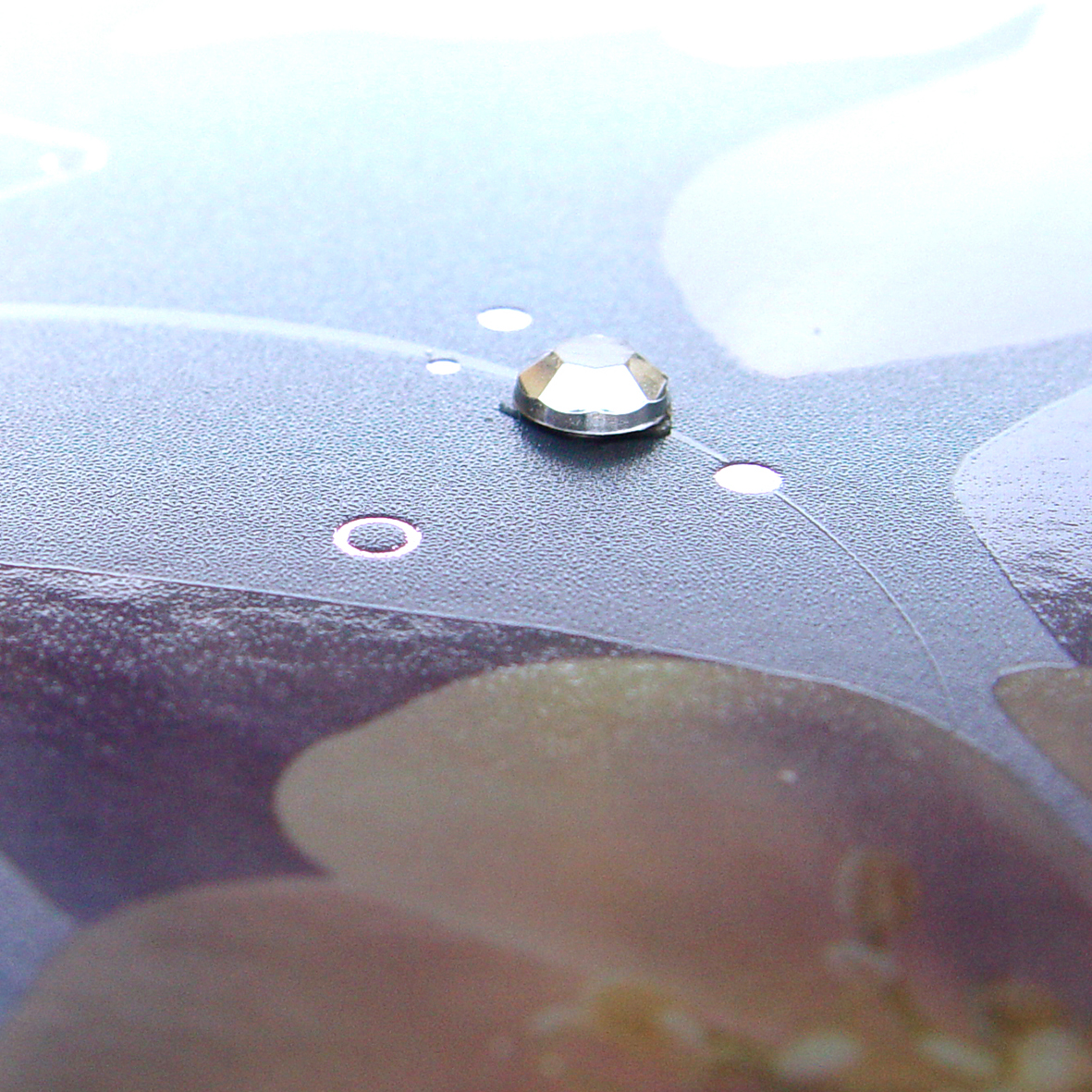

This technique offers the possibility to highlight the graphic elements or parts.

A thick layer of varnish is applied to selected areas of the paper, which dries immediately after exposure to UV radiation, leaving a smooth and shiny surface, which attracts attention to one of the specific parts. UV varnishing is one of the ways to breathe an elegant finish into our products.

We use a flat cut, it is precise and the most variable. The material is cut using a die-cut mold and a die-cut machine. Spectacular works are created by adding cutouts and special transparent graphic papers. The artist proposes combinations and with their help tries to enhance the impression of the finished work.